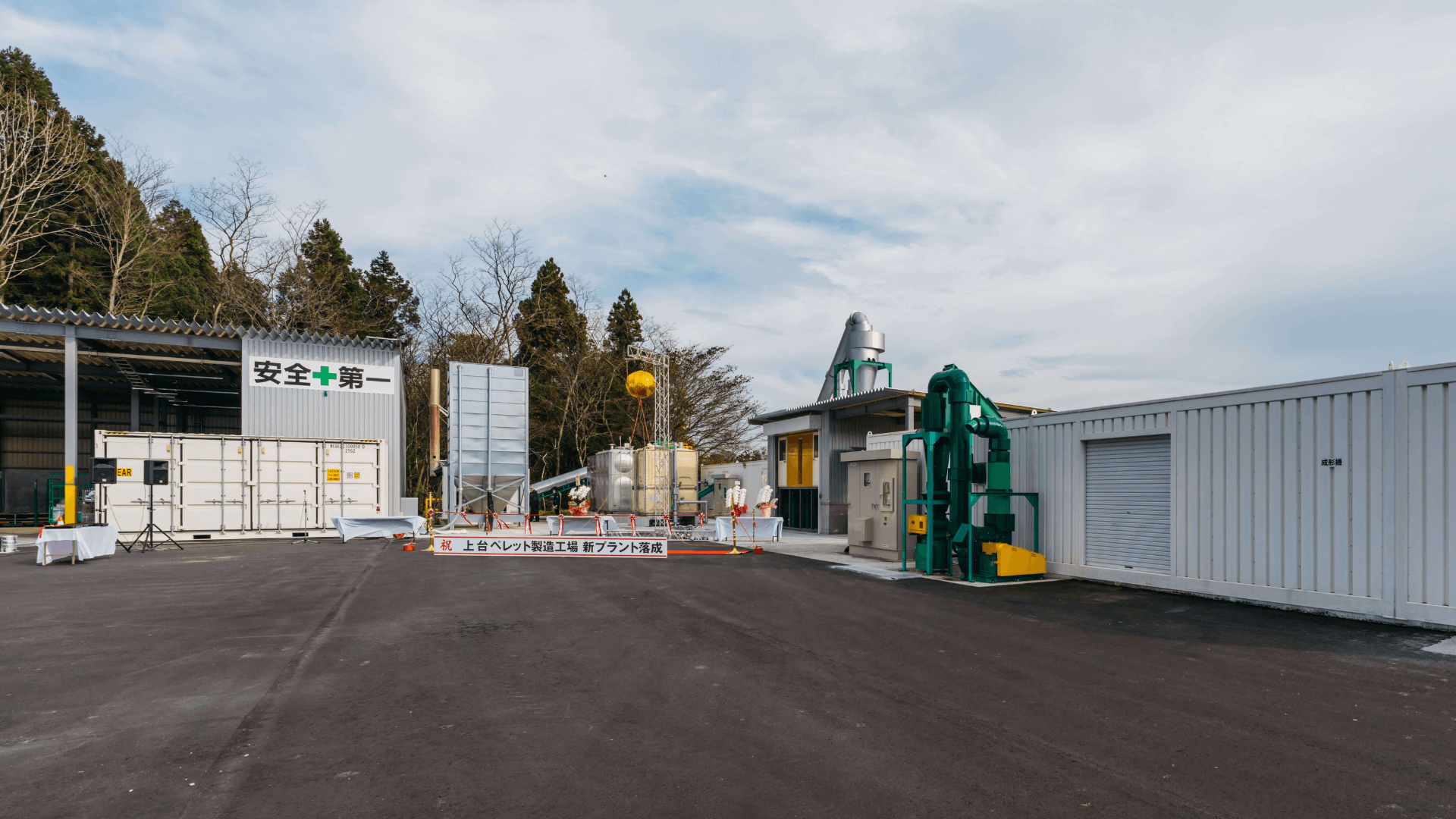

Project Description

Seeds KK is a wood pellet factory in Tanagura Town in Central Japan who were looking for solutions to reduce the cost and carbon footprint of their wood pellet production process.

Their solution was to install a wood pellet fired combined heat and power boiler which was capable of providing 120kw per hour of heat which was used to dry the sawdust used in the manufacturing process and and 50kw per hour of electricity which was used to power the pellet mill.

Biomass Silo Systems were contracted by the boiler company, Wegscheid Entrenco GMBH to provide a 14.0 ton capacity wood pellet silo with dimensions 2.4m X 2.4m X 5.43m high to store wood pellets on site.

The 60 degree hopper base ensures that the silo drains completely and eliminates the need for periodic cleaning of dust while the look of the square silo fits well with the containerised CHP boilers provided.

The flat packed nature of our silos mean they can easily be shipped and used almost anywhere in the world and this is one of over 25 silos that we have supplied for CHP projects in Japan over the last number of years.